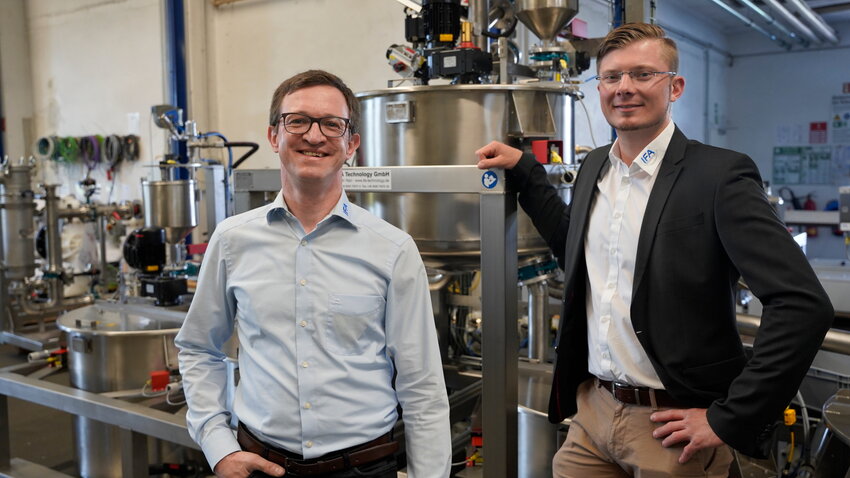

The basis for every successful process optimization is a precise analysis of the existing processes. At IFA Technology, we start with a detailed examination of your production processes in order to develop targeted solutions that meet your specific requirements. In the field of weighing, mixing and dosing technology, we offer precise coordination of the individual steps, which results in a significant increase in efficiency.

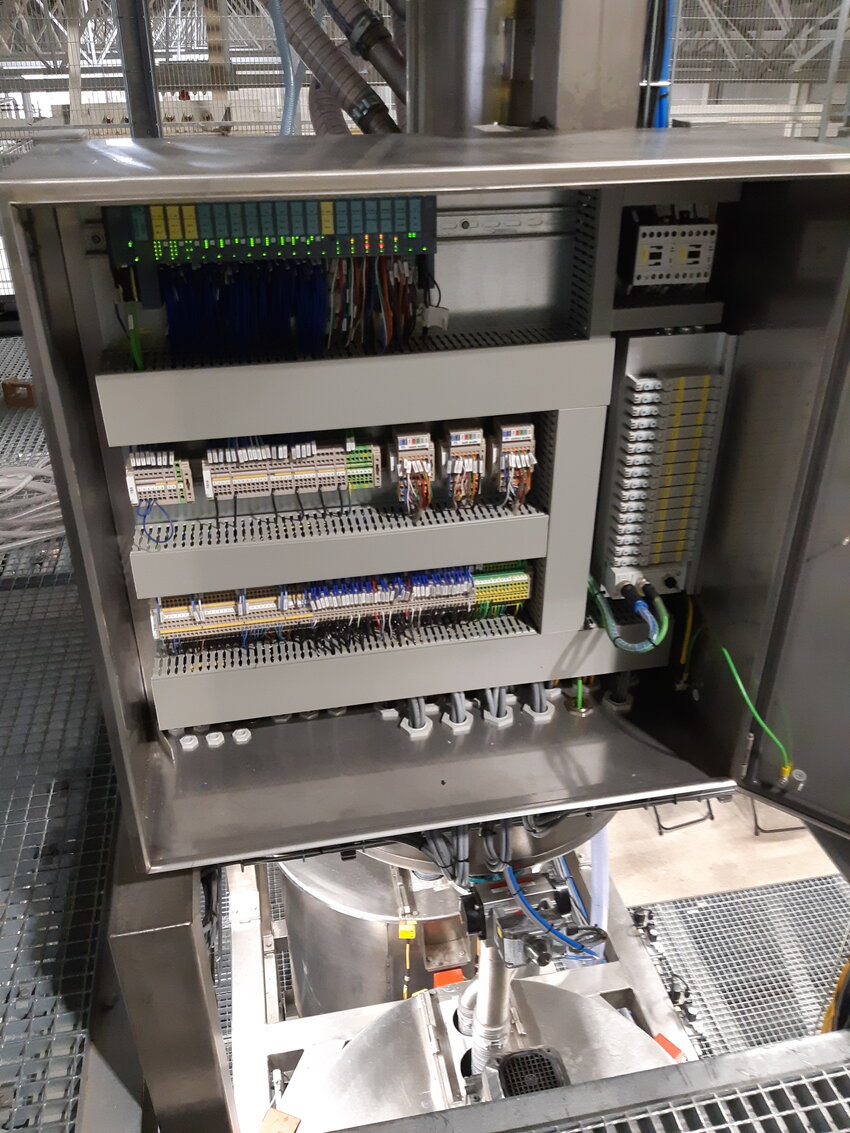

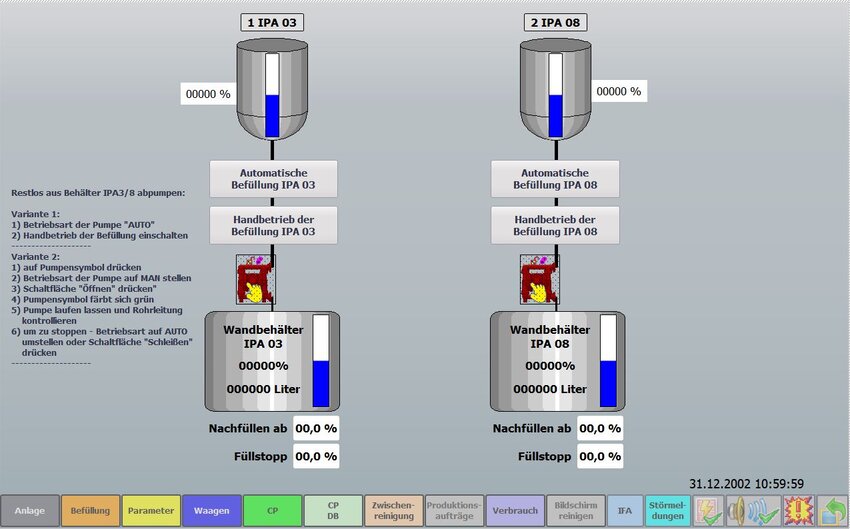

By using innovative control technologies – such as recipe control, PLC programming and visualization – we optimize the entire production process by automatically and precisely controlling parameters such as dosing quantities, stirring times and temperatures. This is how we ensure that product quality remains consistently high, material losses are minimized and energy consumption is reduced.

Your advantages of process optimization with Smart IFA

- Minimization of rejection rates thanks to precise control and monitoring

- Reduction of downtime through modern remote maintenance

- High flexibility for different recipes

- Optimization of resources to reduce material waste and energy consumption