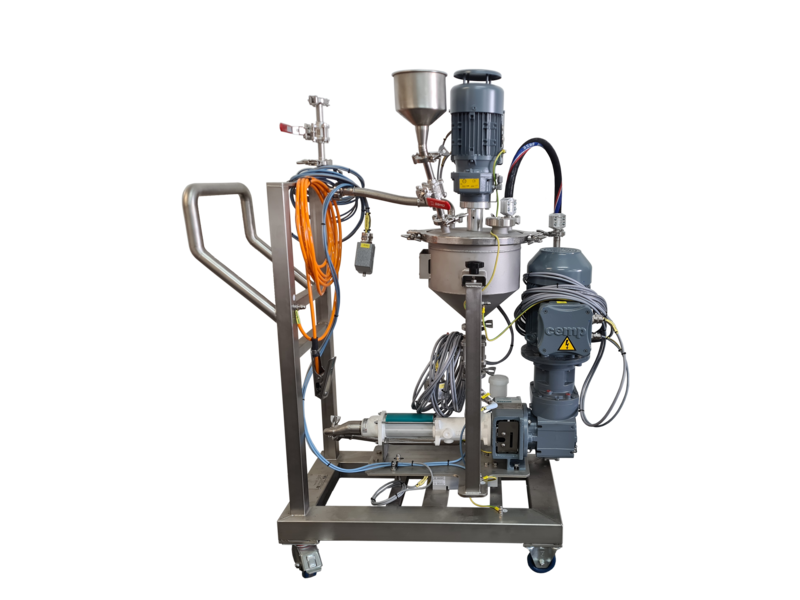

Mobile container technology offers a safe, clean and efficient solution for raw material and product handling. The mobile stainless-steel containers from IFA Technology enable controlled, low-contamination transport of raw materials, intermediates and sensitive media – ideal for hygienic production environments in the pharmaceutical, chemical and food industries.

With robust construction, smooth and easy-to-clean surfaces and high mobility, the containers support flexible workflows, simplify batch changes and reduce manual handling. This ensures reproducible, reliable and hygienic material supply.

Whether powders, granulates, liquids or demanding intermediates – our mobile container systems provide a flexible, hygienic and process-safe solution for companies looking to optimise their raw material and product handling.

Request mobile container