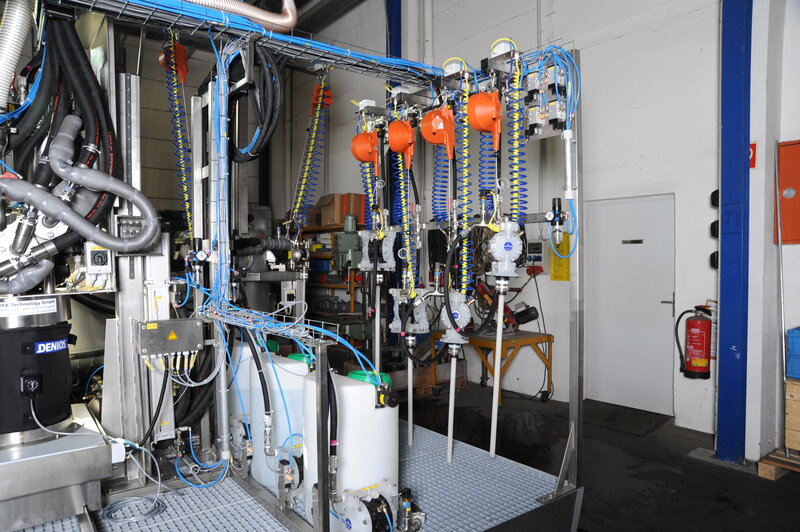

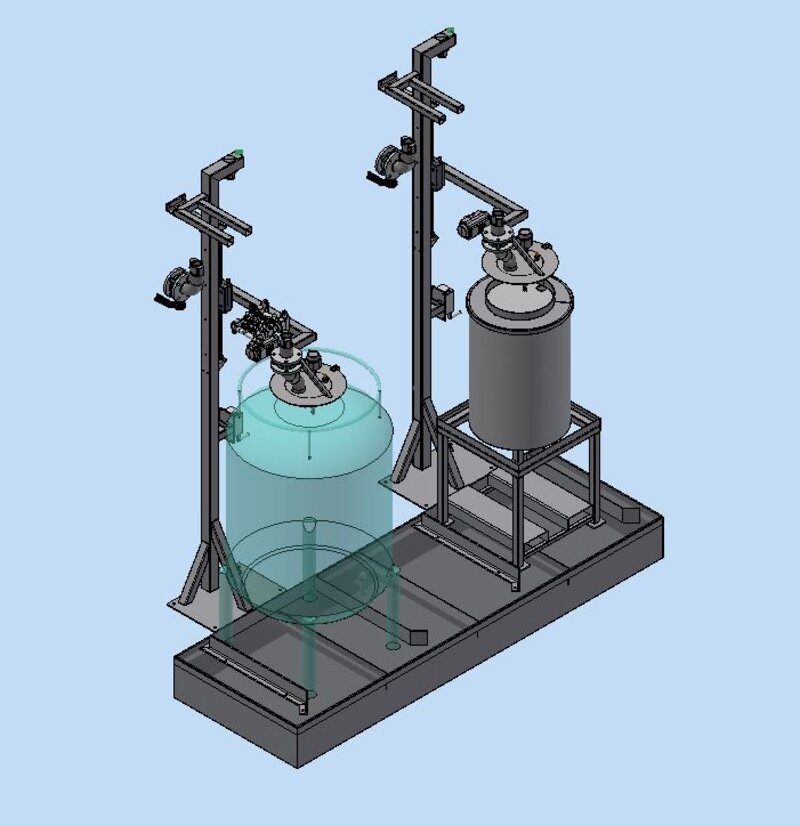

Our systems impress with their flexibility and modern technology. They adapt to different barrel sizes and individual production requirements, ensuring seamless integration into existing lines. A dust- and gas-free system with the appropriate extraction improves air quality and minimizes health risks. The automated systems increase efficiency, reduce errors and increase product quality. Seamless integration into existing systems allows for continuous production without downtime.

IFA Technology has developed customized solutions for a wide range of applications, covering a variety of raw materials. These include pasty media, hazardous powders and highly flammable liquids. We have developed specific solutions for emptying and filling barrels, containers, and canisters that are tailored to the special requirements of these materials, ensuring maximum efficiency, safety and precision in the respective processes.