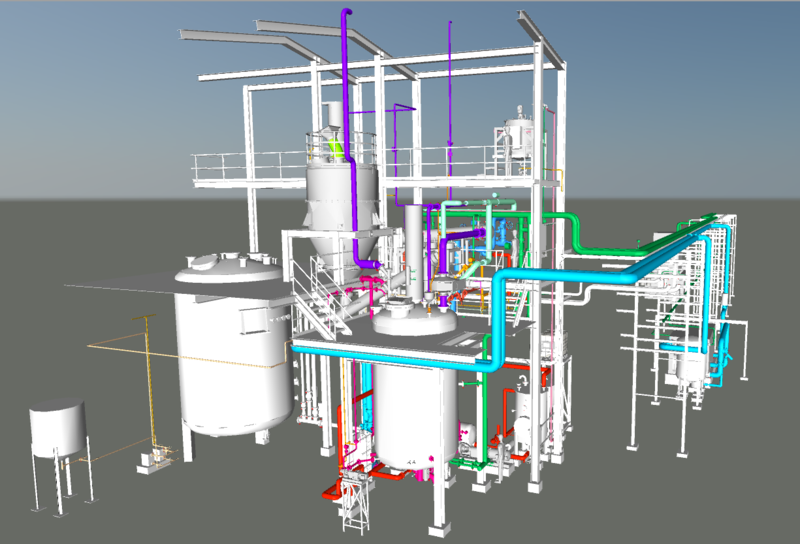

Glue reactors and glue mixing plants are specialized systems for producing glues and adhesives, also called “glue kitchen”. They play a central role in chemical and industrial production, particularly in the production of white glues, epoxy adhesives, and polyurethane adhesives. Adhesives are used in the wood processing, packaging, electronics, and construction industries. The design of the glue reactors enables the exact control of the necessary reaction conditions to produce adhesives with the desired properties, such as viscosity, drying time, and adhesive strength.

Glue kitchens from IFA Technology are characterized by a high degree of flexibility and adaptability to different production requirements. A major advantage of industrial glue production is the precise control of temperature, pressure, stirring speed and pH value. The integrated automation enables simple and exact monitoring and adjustment of production parameters, resulting in consistently high product quality.