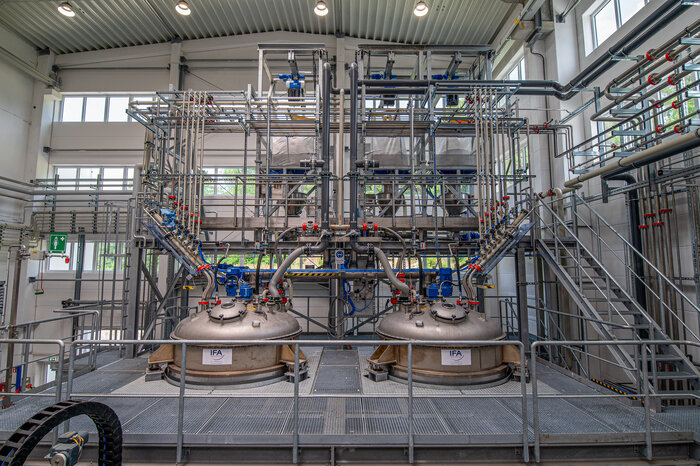

The operation of a reaction system is designed to enable the desired chemical reactions under optimum conditions. This is achieved by precisely controlling parameters such as temperature, pressure and mixing speed. Raw materials, also known as reactants, are introduced into the reactor where they react with each other under controlled conditions. The systems enable precise dosing of the components, which can be done manually or automatically as required. By using advanced dosing systems - gravimetric, volumetric or combined - the exact recipe is maintained at all times, resulting in consistently high product quality.

The reactors are also equipped with modern systems for temperature and pressure regulation, which ensure stable process control even under extreme conditions. Continuous monitoring of viscosity and pH value during the entire reaction process ensures that the product quality remains constant and undesirable side reactions are avoided.

Request Reaction system