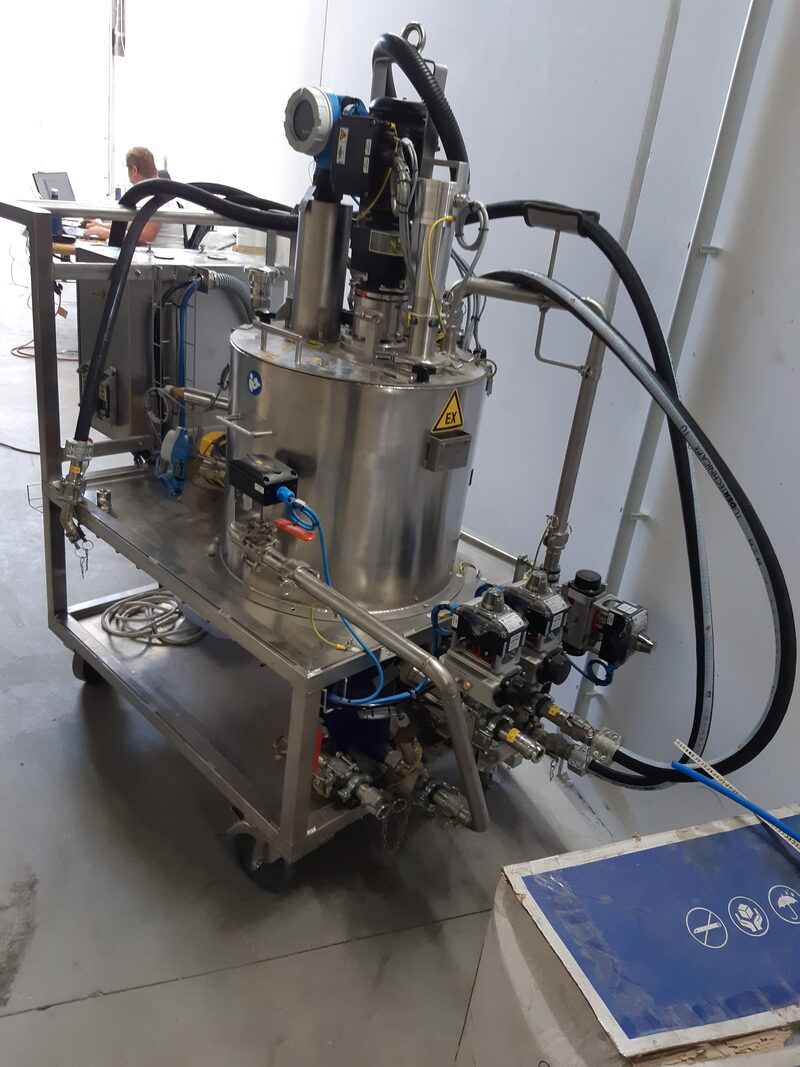

IFA Technology offers viscosity control systems that increase efficiency and reliability in production processes. They enable continuous real-time monitoring and reduce manual intervention, saving time and costs. They ensure consistent product quality through precise control and reduce rejects and rework. Process parameters are automatically adjusted in the event of deviations.

Real-time monitoring and automatic optimization

Viscosity control systems continuously record the viscosity of liquids or pasty materials during the production process Real-time monitoring enables immediate adjustments to the process parameters This keeps the viscosity within the desired specifications, which is essential for consistent end product quality

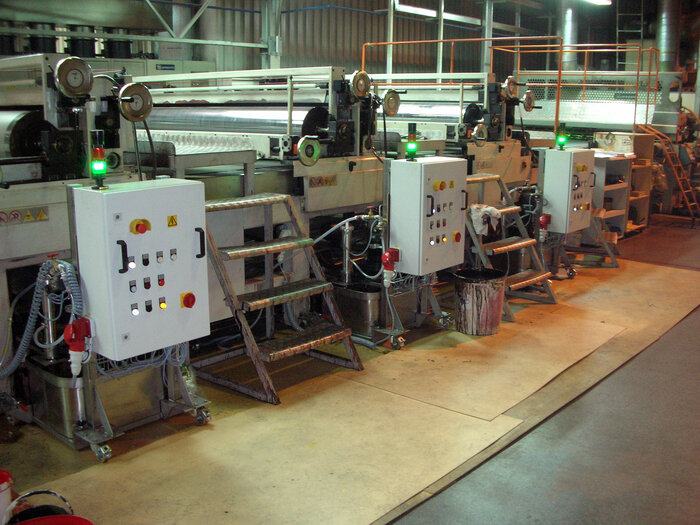

The systems prevent production downtimes or quality fluctuations by intervening immediately in the event of the smallest deviations. They are particularly valuable for sectors such as paints and coatings, the pharmaceutical industry, semiconductor technology and solvent-based impregnation processes.

Request viscosity control system