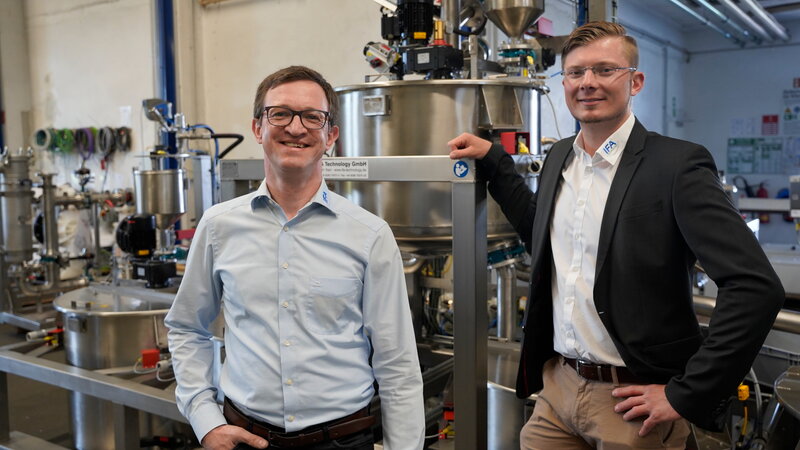

Powder wetting systems are indispensable machines for industrial mixing processes in which powdery substances have to be incorporated into liquids. The powder wetting process ensures an even and lump-free distribution of powders and granulates. In process engineering, this refers to the complete displacement of air between the powder particles by a liquid. Powder processing systems are of crucial importance in numerous sectors, such as the food, building materials and pharmaceutical industries.

Equipped with advanced technology, powder wetting systems prevent the formation of dust and ensure that the powder is reliably and efficiently dispersed in liquids. They ensure an exact and homogeneous mixture of powders and granules, significantly improving both the efficiency of production processes and the quality of the end products. This leads to higher product quality, less waste and an overall optimized production output.