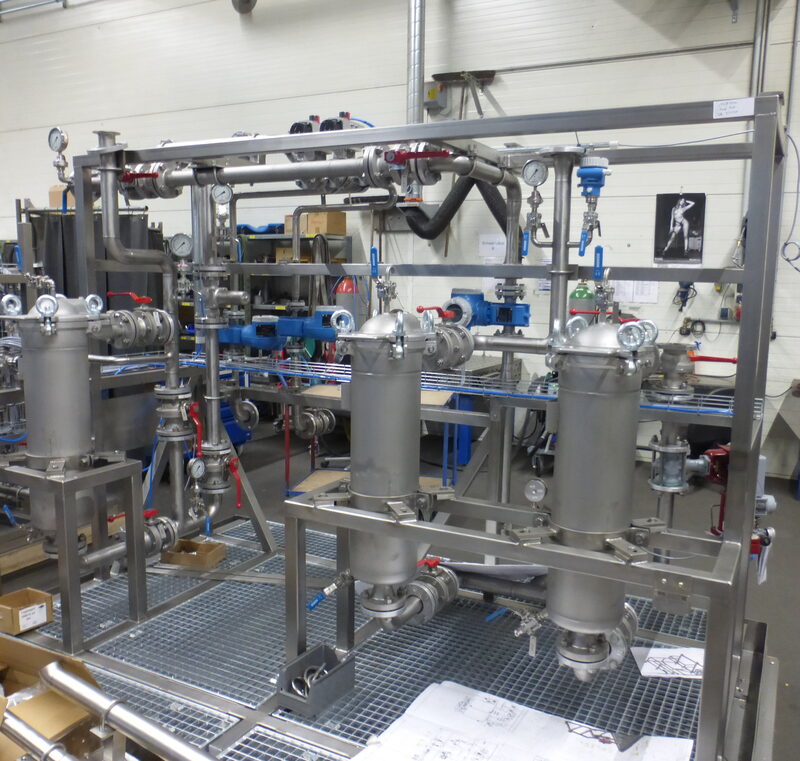

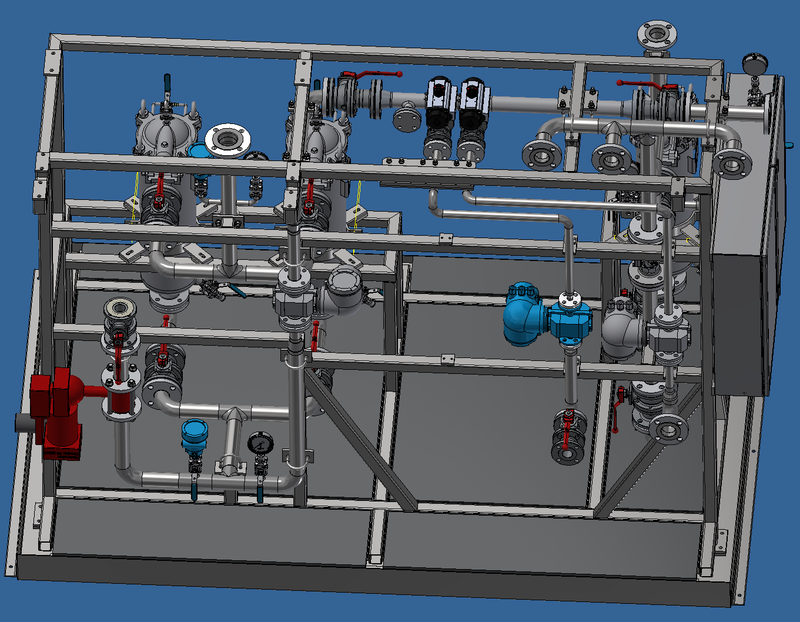

Industrial inline mixers are indispensable equipment in processes where continuous and uniform mixing is required. They offer an efficient solution for mixing liquids, solids and materials of different viscosities - without interrupting the production process. This technology is primarily used in the chemical industry, in paint and varnish production and in the manufacture of plastics and lubricants.

In contrast to batch mixing systems, where the mixing process takes place in separate batches, inline mixers integrate seamlessly into the ongoing production process. They mix liquid and solid components directly in real time without stopping or changing the process. This continuous mode of operation increases efficiency and ensures consistently high product quality.

Inline mixing systems are characterized by their flexibility: They can be used for a wide range of applications, from processing low-viscosity substances to highly viscous media. Depending on the requirements, inline mixers can be equipped with various stirring systems such as rotor-stator principles, propellers or turbines, or they can work with static stirring systems, as is common with static mixers. This allows the mixer to be optimally adapted to the physical properties of the materials to be processed.

Thanks to their high efficiency and precise control, automated inline mixers offer a cost-effective and powerful solution for industrial applications where speed, precision and consistent quality are crucial.