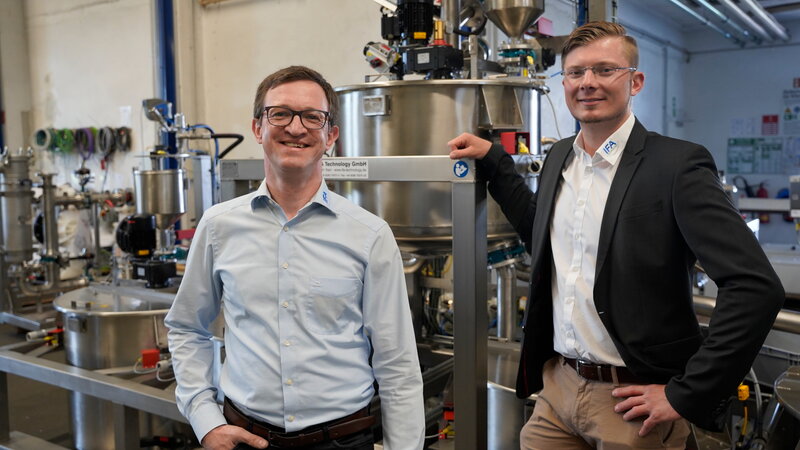

As a leading international company in process engineering, IFA Technology offers innovative solutions for many industries. Benefit from 45 years of experience in weighing, mixing, conveying, and dosing solid and liquid materials.

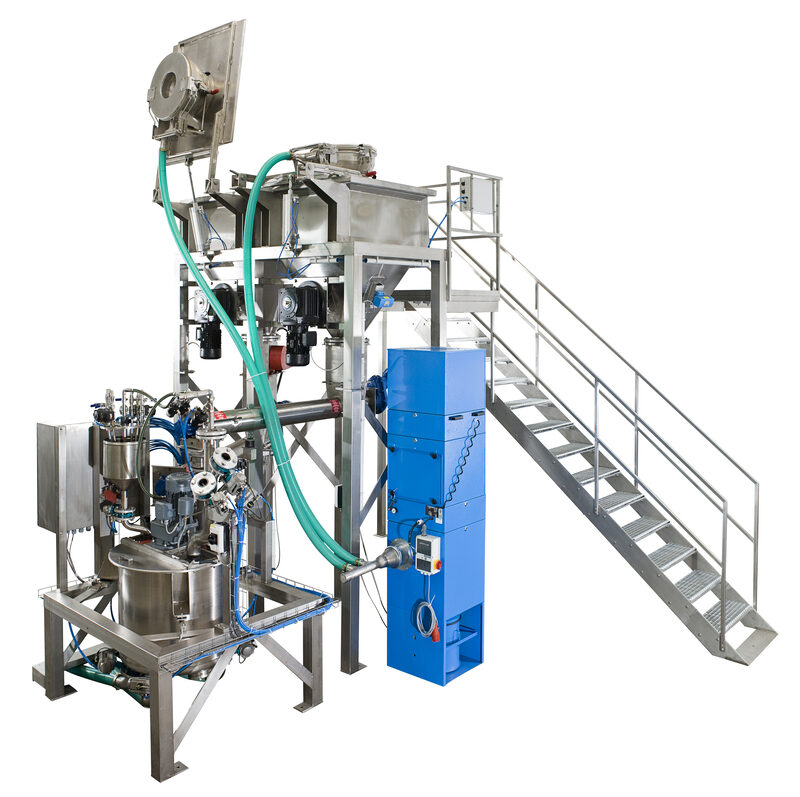

Our wide range of systems is specially designed to meet the requirements of various industries and applications. In addition to industrial mixing systems, we provide reliable solutions for raw material and product handling. These include conveyor technology, storage and silo systems, big bag systems, and discharge and dosing systems.

Customized and automated systems help you optimize production processes, improve material flows, and reduce operating costs. Our solutions offer high flexibility and precision. Contact our experts for individual solutions that are precisely tailored to your needs.

Contact ussales@ifa-technology.de